#makeovermonday - How to restore a Mercedes-Benz 280 SL Pagoda? - part 3.2

From the exterior and the interior to the special equipment: The process of the restoration takes different steps until we can deliver you a perfectly restored Mercedes-Benz 280 SL Pagoda. But what exactly does a classic car-restoration look like? We look forward to giving you an insight into our classic car manufactory and professional restoration. A look behind the scenes, at the craft of the passionate and experienced automobile lovers of our Arthur Bechtel Classic Motors Manufactory-team: this is what awaits you in our #makeovermonday series.

PART 3 - THE HEART

THE CENTERPIECE OF A CLASSIC CAR - PART 2

What would a vehicle be without its engine? Of course, the centerpiece plays a very special role in the restoration of our classic cars. We went into detail in last weeks article on the work on the centerpiece. Did you miss the blog post? Read the post: here! In addition to the engine, there are a few other elements that are being revised during the restoration of our Mercedes-Benz 280 SL Pagoda, such as the transmission, the brake system or the injection pump. But what does this step of the classic car-restoration look like in detail?

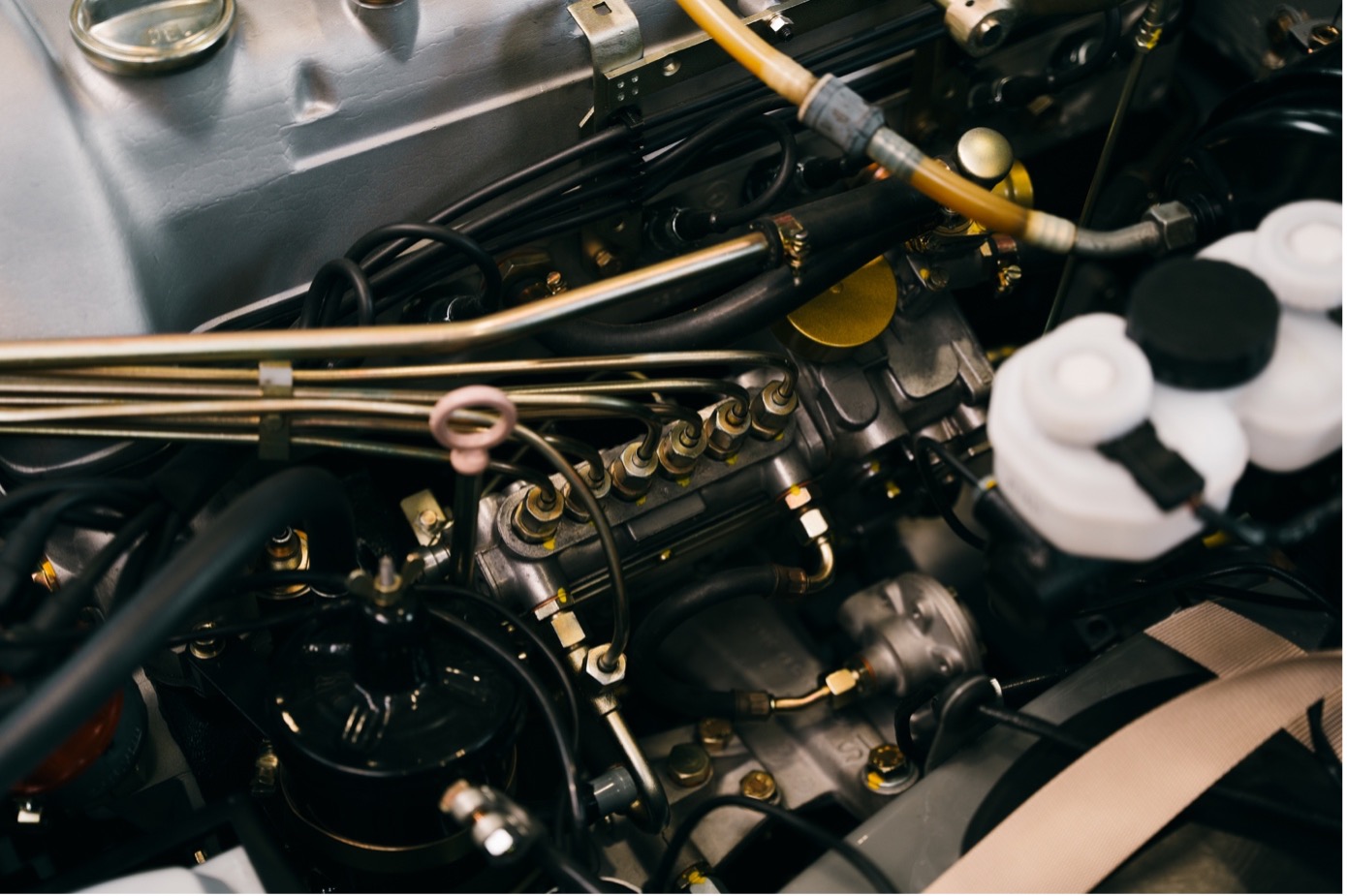

Injection pump

In the case of our restoration object, it is an injection pump with the identification PES 6 KL 70B / 120 R 25, which fits perfectly with our M130 engine of the Mercedes-Benz 280 SL Pagoda. The injection pump, on the one hand, showed severe leakage and, in interaction with the still functional engine, poor performance. During the restoration process, we are completely overhauling this six-piston-injection pump, both technically and visually, and adapt it to our newly built engine.

In order to make a first inspection with the pump, we first put the six-piston-injection pump on our test device. Here an operation is simulated, which provides us first information about the condition. The following components of the pump are checked: the check of the leakage oil lock and the function of the start magnet as well as the setting dimensions of the warm-up regulator. In addition, a zero point is set and the maximum control range, the full-load control range and the constant delivery at full load and the delivery rates at partial load are measured. In the same step, the injection valves are also checked for opening pressure, spray pattern and tightness. During this test procedure, a test report is created in order to compare the results with those of the revised pump later.

In the further process, the pump is dismantled, cleaned, the ball pressure valves are cleaned in the "open" state and all six pieces are deep-cleaned and backwashed in a special ultrasonic bath. The parts are then dried and reconditioned, all valves are checked for leaks and replaced if necessary.

After the cleaning, the pump is reassembled and adjusted based on the basic settings. Here we carry out the following work to adjust and complete the pump:

• Checking and adjusting the guide part stop and the control of volume and air

• Setting the sensing roller to the middle position

• Setting the transmission

• Checking and setting the height correction (dimension "c")

• Adjusting the idle stop and the external adjustment lever (assignment)

• Presetting of the control springs

• Checking and setting the warm-up correction, the constant delivery at full load, partial load quantities and the start quantity

• Seal the pump with locking varnish

• Creation of a test report

After all the basic settings have been made, we create a test report again and compare this with the first report. The final settings of the injection pump are carried out together with the engine on the engine test bench. Together with the ignition settings, this six-piston injection pump makes a decisive contribution to the driving pleasure of the Mercedes-Benz 280 SL Pagoda.

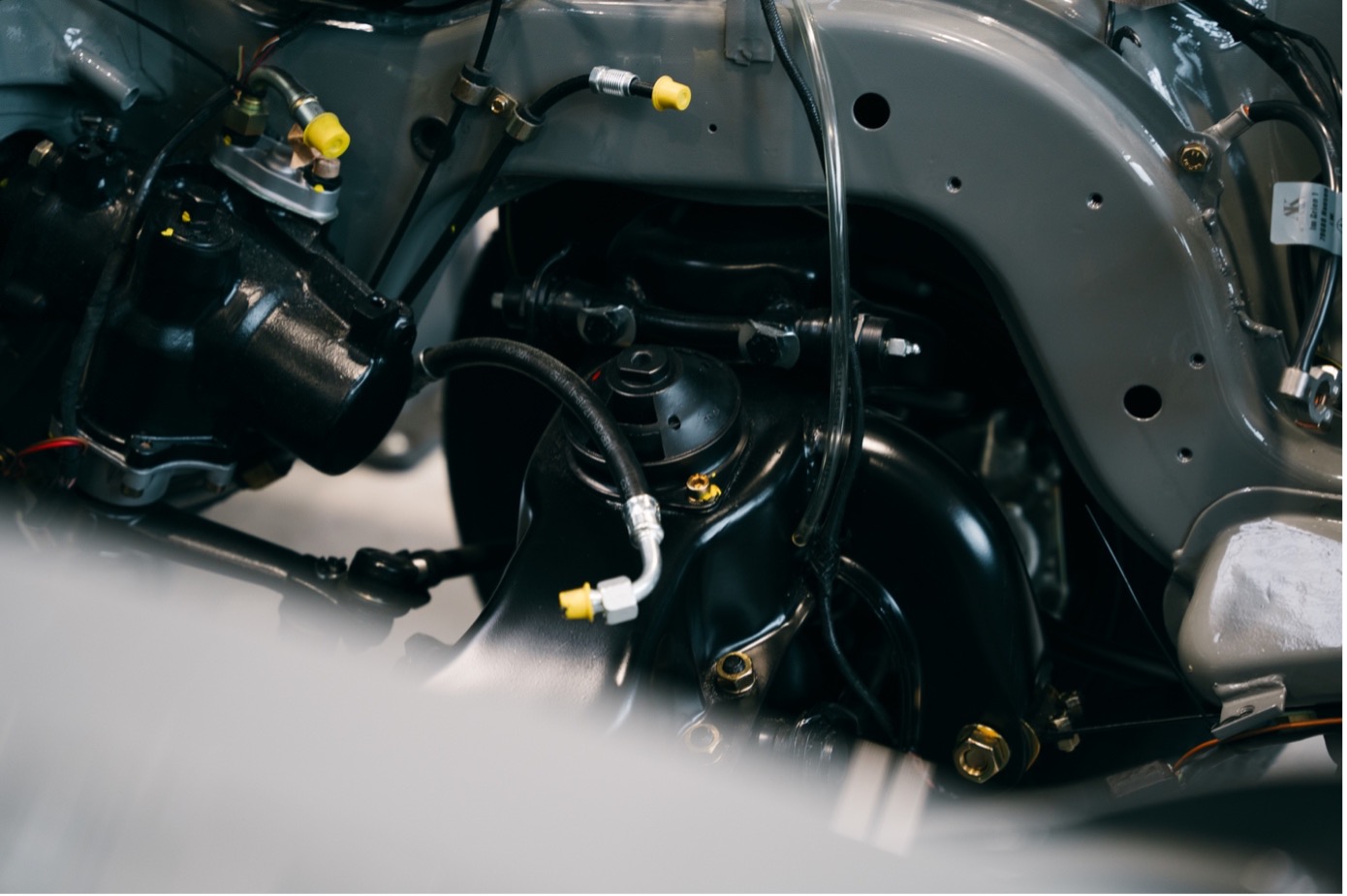

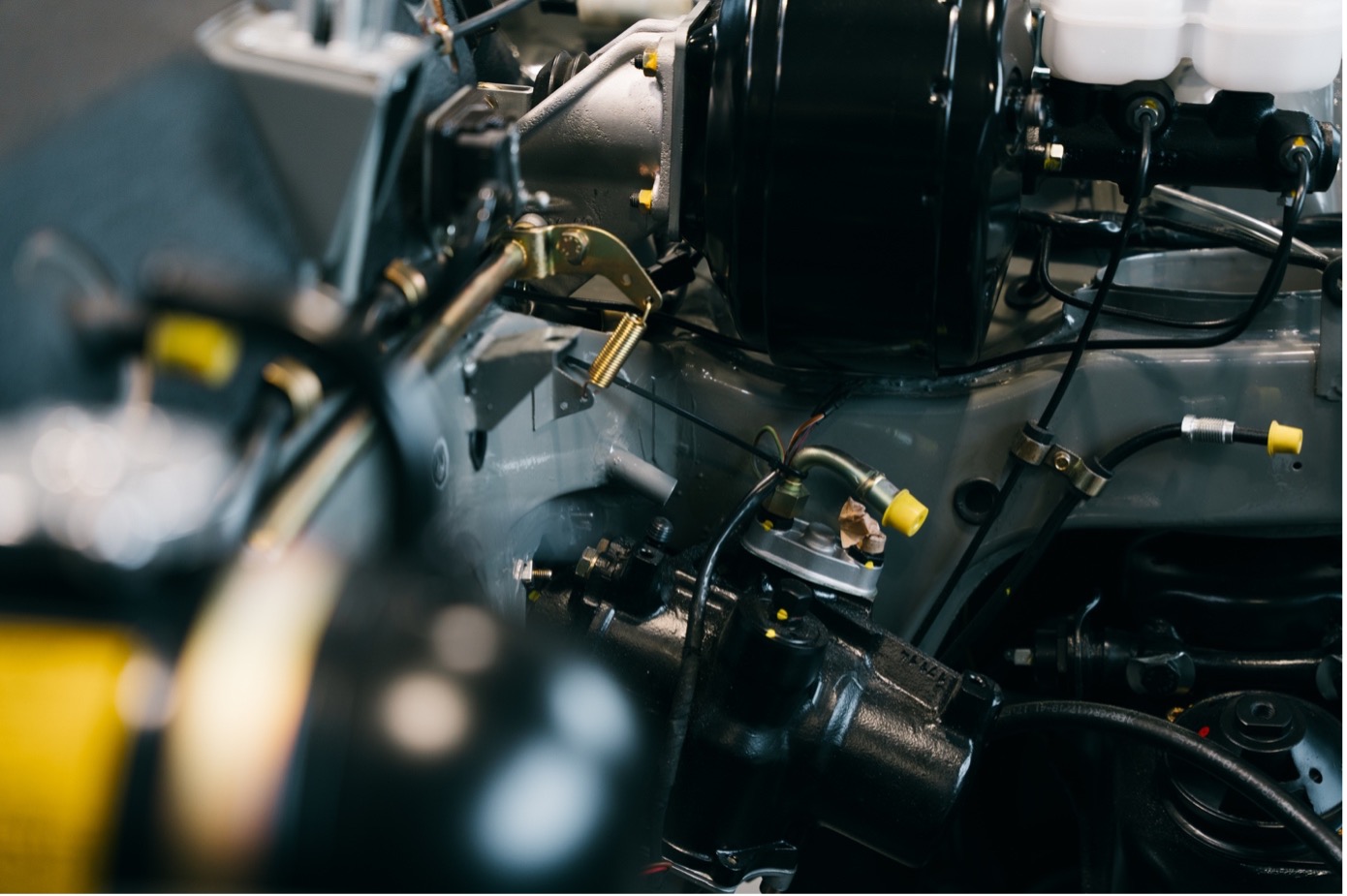

Power steering gear

The Mercedes-Benz 280 SL Pagoda was the first SL with extensive safety measures. The "Pagoda" has a stiff passenger cell and crumple zones as well as easily deformable bow and rear segments. In addition, there are no hard corners and edges in the interior. Seat belts were also available as an option. And also with the steering gear, attention was paid to the safety aspect, because the steering gear was moved to the bulkhead and the steering column was bent and provided with joints that prevent the dreaded lance effect in an accident.

During our restoration process, we completely overhaul the original power steering: We remove the power steering unit including the steering column during the dismantling process and bring the entire unit to our mechanics area. Here the power steering gear is then completely dismantled, cleaned and checked for wear. In the next steps we clean the housing and the housing cover made of steel, these components are then sandblasted, cleaned again and painted accordingly. The housing cover made of aluminum is also cleaned and glass beads blasted. After all cleaning and preparation work has been completed, all threads are checked and recut. In addition, all seals and sleeves are newly procured from the Mercedes-Benz parts service and used accordingly. The steering gear is then assembled together with all new parts and the steering play is adjusted. In the last step, the steering gear and steering column are brought together and later reinserted in the new vehicle.

Preliminary result

The centerpiece of our Mercedes-Benz 280 SL Pagoda is now in the middle of the restoration process and the extensive work continues on the transmission. We are pleased to present you next week (on September 20th, 2021) another intermediate step in the restoration of the Mercedes-Benz 280 SL Pagoda in our #makeovermonday series: "The heart - Part 3".

Follow us on

Instagram: @arthurbechtelclassicmotors