#makeovermonday - How to restore a Mercedes-Benz 280 SL Pagoda? - part 3.1

From the exterior and the interior to the special equipment: The process of the restoration takes different steps until we can deliver you a perfectly restored Mercedes-Benz 280 SL Pagoda. But what exactly does a classic car-restoration look like? We look forward to giving you an insight into our classic car manufactory and professional restoration. A look behind the scenes, at the craft of the passionate and experienced automobile lovers of our Arthur Bechtel Classic Motors Manufactory-team: this is what awaits you in our #makeovermonday series.

PART 3 - THE HEART

THE CENTERPIECE OF A CLASSIC CAR - part 1

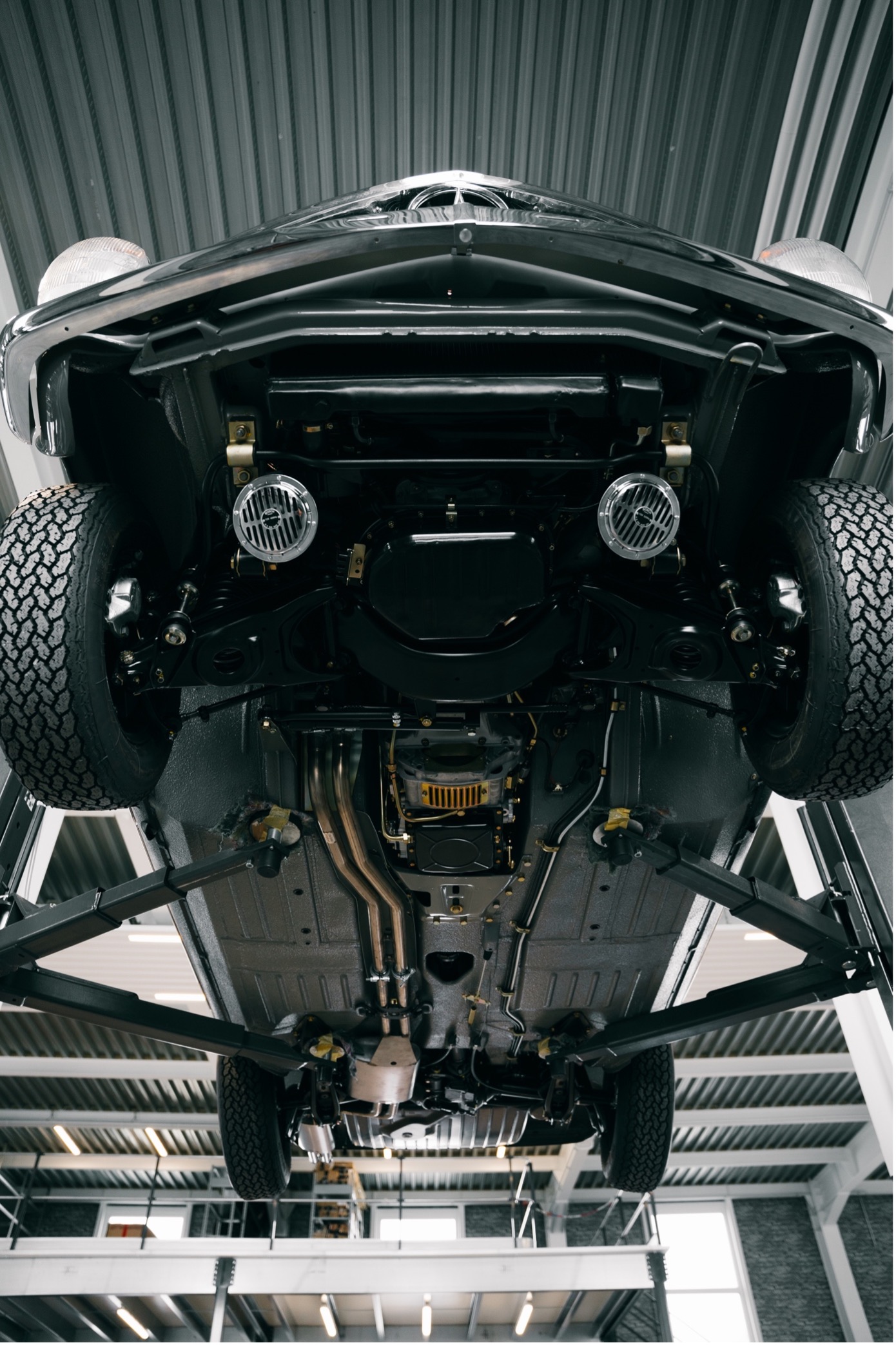

What would a vehicle without its engine be? Of course, the centerpiece plays a very special role in the restoration of our classic cars. In addition to the engine, there are a few other elements that are being revised during the restoration of our Mercedes-Benz 280 SL Pagoda, such as the transmission, the brake system or the injection pump. But what does this step of the classic car-restoration look like in detail?

The engine

In order to describe the restoration process, we will explain our individual steps with a Mercedes Benz 280 SL (M130) engine, which we took out of our restoration. The engine was in in functional condition at this step. If the classic was a barn find, the approach would be slightly different.

In this case, as a first step, we made a function test of the engine in the vehicle in order to obtain first findings. In order to receive complete overview the engine is removed from the vehicle fully and the transmission is removed from the flange. In order to simulate a test run without the effect of load, we set up the engine on our engine test bench, fill it with all relevant fluids, connect all electrical components and prepare the engine for a test run. After the test, the engine is disconnected from the test bench and is completely dismantled. The attachments are optically checked and pre-sorted.

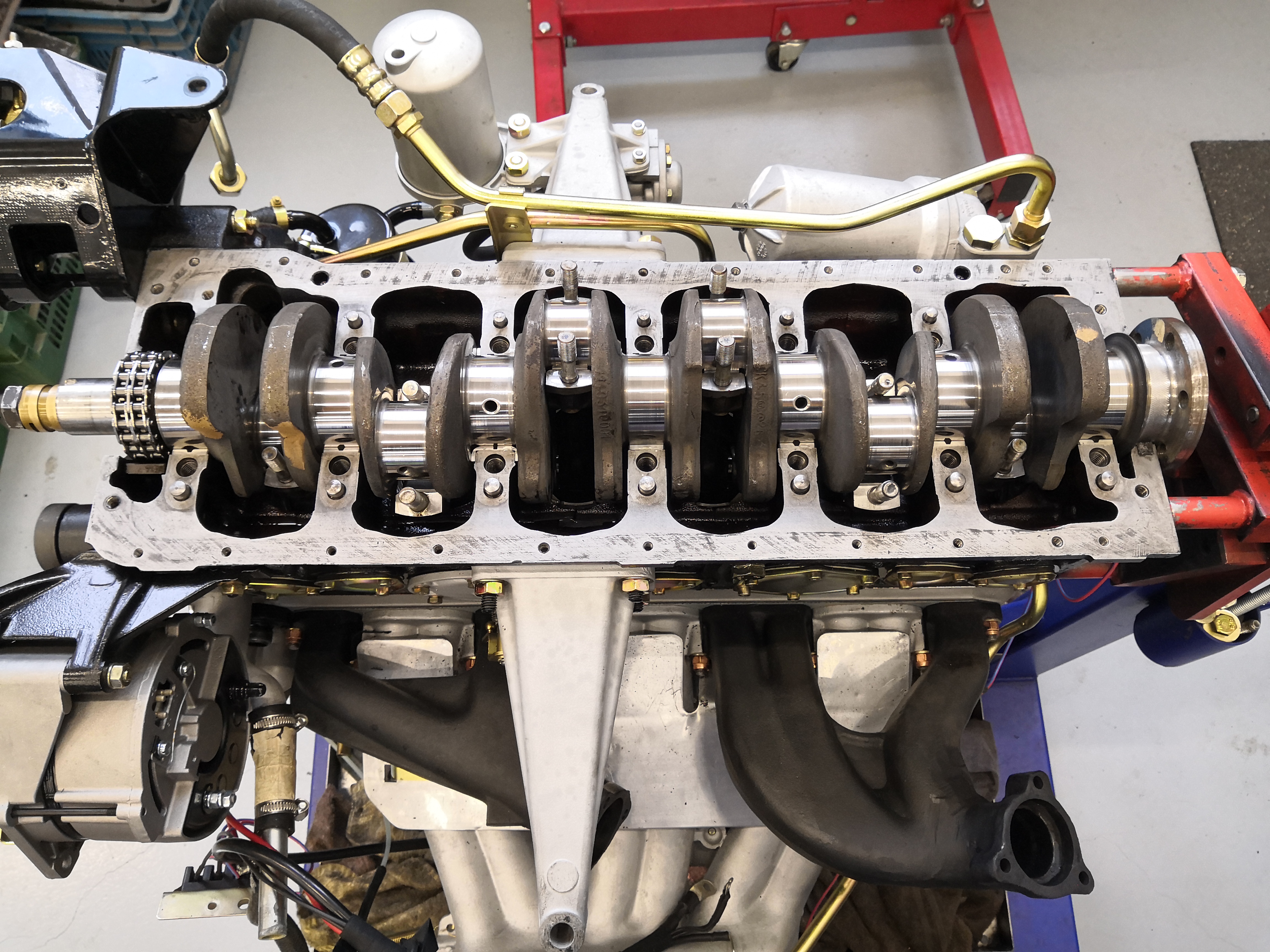

In the next step, the engine block is measured and prepared for processing. The crankshaft main bearing caps are cleaned and sandblasted, all sealing on the block are removed and all sealing surfaces are sanded, the main bearing line is lapped, the bearing cover is mounted and the bearing line is being measured. In addition, the crankshaft including all bearings is measured and the engine block, oil and water channels are cleaned, the engine block will be removed from old paint.

The cylinder head

During the overhaul of the cylinder head, it is first dismantled. Then the individual parts are cleaned, the cylinder head is measured and the combustion chambers are cleaned. The cylinder head is glass bead blasted and cleaned, various threads in the head are checked and, if necessary, repaired. Here it is important to make a leak test with the cylinder head. Valve guides are renewed, the cylinder head is measured and, if necessary, planned. The new valves are then checked for leaks, the valve adjusting pins are repaired and sealed. The renewal of the camshaft bearing is also part of the restoration work. In the last step, the cylinder head is completed.

The engine block & attachments

After drilling and honing, the engine block is first cleaned, masked accordingly and painted with a 2K- paint. The connecting rods are measured and weighed, all weights are adjusted, after which all connecting rods are weighed again and the oil injection hole for the cylinder lubrication in all connecting rods is checked.

To complete the engine block, the oil return is reworked on the crankshaft at the rear, the main bearing is calibrated, the crankshaft is re-positioned and the connecting rod bearing is calibrated. In addition, the cylinders are measured after drilling and the pistons are assigned to the cylinders. This is followed by the assembly of the pistons with the connecting rods, and the Borgmann sealing ring is milled into the engine block. In the last step, the pistons are inserted into the engine block, the oil channels are closed and the water cap is mounted on the block.

To recondition the engine add-on parts, all aluminum parts are cleaned and blasted with glass beads. The steel add-on parts are also blasted with glass beads and are painted accordingly. In the valve cover, the protective plate for the engine ventilation is riveted, the carbon is blasted out from the plate and the valve cover and the plate for the engine ventilation is riveted.

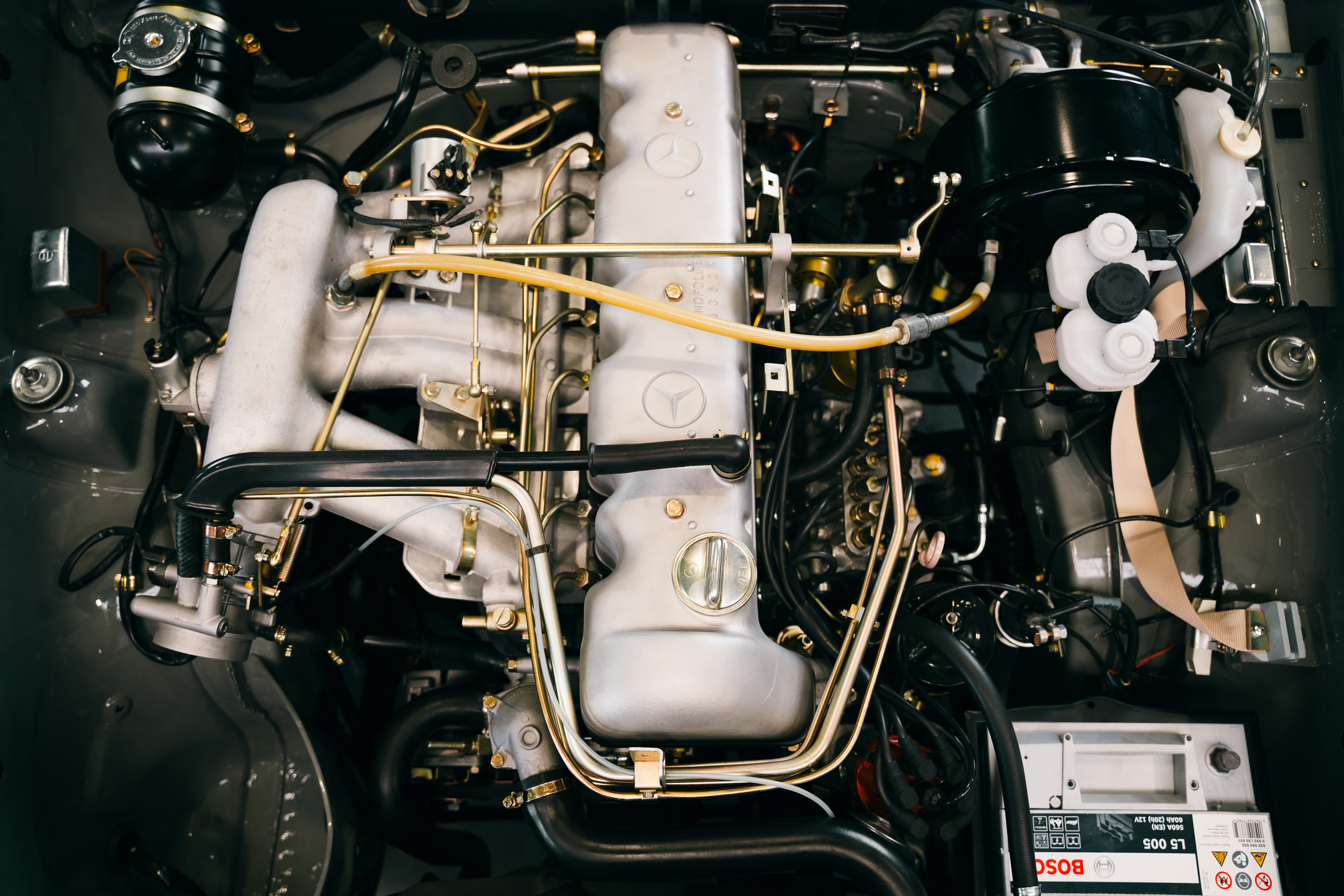

The engine completion

The engine is completed with new, partly blue and yellow galvanized, reconditioned parts. The cylinder head is mounted on the block and the timing is set with the dial gauge. The oil pump is overhauled, the oil pan is installed and the slide rails are renewed. The injection pump is then attached.

The engine is sealed, the original distributor installed and the ignition cable set renewed. The cold start valve is also renewed, repaired and removed from the pressure head in order to check its function.

The test bench work

Testing is our keyword for the next step of the process – the engine is put on the test bench and filled with the required fluids. The test bench work look as follows: The engine is put into operation and is brought to temperature. Then, all components are checked for leaks and settings. Ignition settings can be fine-tuned in the test run. The test work takes place over several days, as the engine must always cool down in order to simulate both - a cold and a warm start. It is also necessary to set the CO-value when the engine is warm and this is checked several times and fine-tuned if necessary. During the test work, the cylinder head is tightened and the valves are adjusted when the engine is cold. The engine is then ready for installation. (After a mileage of 1000 km, the cylinder head must then be retightened.)

Preliminary result

The centerpiece of our Mercedes-Benz 280 SL Pagoda is now in the middle of the restoration process and the extensive work continues on the injection pump, transmission and steering. We are pleased to present you next week (on September 13th, 2021) another intermediate step in the restoration of the Mercedes-Benz 280 SL Pagoda in our #makeovermonday series: "The heart - Part 2".

Follow us on

Instagram: @arthurbechtelclassicmotors